According to a recent report, a market research firm predicts a valuation of $948.6 million by 2030 for a certain entity. The projection indicates significant growth potential for the company over the next decade. The report highlights various factors that contribute to this estimated valuation, such as market trends, technological advancements, and consumer demand. This optimistic forecast suggests that the entity can expect substantial financial success in the future, reflecting opportunities for potential investors or stakeholders to benefit from its projected growth..

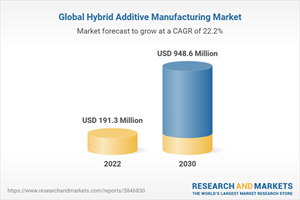

Global Hybrid Additive Manufacturing Market

Dublin, Aug. 29, 2023 (GLOBE NEWSWIRE) — The “Hybrid Additive Manufacturing Market Size, Share & Trends Analysis Report By Material (Titanium, Aluminum, Steel, Nickel, Others), By End-use, By Region, And Segment Forecasts, 2023-2030” report has been added to ResearchAndMarkets.com’s offering.

The global hybrid additive manufacturing market is on the brink of remarkable expansion, projected to achieve a substantial market size of USD 948.6 million by 2030, according to a comprehensive report.

This surge is indicative of a robust Compound Annual Growth Rate (CAGR) of 22.2% from 2023 to 2030, showcasing the escalating adoption and transformative potential of hybrid additive manufacturing.

Convergence of Manufacturing Innovations

The propulsion behind this market surge lies in the escalating adoption of hybrid additive manufacturing within pivotal sectors like aerospace, medical, and automotive. This convergence of manufacturing innovations is set to steer the market’s growth trajectory, opening new horizons for intricate and high-quality production.

Customization Catalyzes Development

In response to the mounting demand for tailored products spanning diverse industries, hybrid additive manufacturing has emerged as a cutting-edge solution. This innovative technology seamlessly marries traditional subtractive manufacturing with additive manufacturing techniques to craft intricate, bespoke, and precision products. Beyond customization, this approach bestows added benefits including minimal material wastage, expedited production, and reduced costs.

Pandemic’s Dual Impact

The COVID-19 pandemic wrought a dual impact on the hybrid additive manufacturing market. Disruptions in global supply chains triggered shortages in raw materials, components, and equipment, affecting the sector reliant on imports. Paradoxically, the pandemic expedited the adoption of additive manufacturing within the medical sphere, highlighting its indispensable role in healthcare.

Key Market Highlights:

-

The titanium segment is poised for exceptional growth with a projected CAGR of 23.4%. This segment’s promise is underscored by the deployment of titanium in 3D printing due to its stellar strength-to-weight ratio, exceptional mechanical strength, and superior corrosion resistance, particularly when compared to stainless steel.

-

Dominating the landscape, the aerospace sector captured a significant 43.1% revenue share in 2022. Advancements in composite materials, including fiber metal laminates and multifunctional materials with structural and thermal properties, are driving the creation of sustainable, lightweight aerospace components.

-

North America commanded the largest share, 39.8% in 2022, poised to maintain its dominance. A thriving landscape of automobile, machinery, electronics, defense, healthcare, energy, and aerospace industries in the region are propelling the demand for hybrid additive manufacturing.

-

Hoganas AB, a pioneering metal powder producer, marked a significant milestone in April 2022 by introducing a new line of titanium powders tailored for additive manufacturing. This strategic expansion caters to the surging demand for 3D printing applications, offering a cost-effective and reliable solution.

Key Attributes:

-

Forecast Period: 2022 – 2030

-

Estimated Market Value in 2022: $191.3 Million

-

Forecasted Market Value by 2030: $948.6 Million

-

Compound Annual Growth Rate: 22.2%

-

Regions Covered: Global

Navigating Market Dynamics:

-

Drivers:

-

Restraints:

-

Challenges:

Pioneering Companies at the Vanguard:

-

Materialise

-

Hoganas AB

-

GENERAL ELECTRIC

-

Renishaw plc.

-

3D Systems, Inc.

-

GKN Powder Metallurgy

-

Sandvik AB

-

ExOne

-

voxeljet AG

-

CRS Holdings, LLC.

For more information about this report visit https://www.researchandmarkets.com/r/kxyqed

About ResearchAndMarkets.com

ResearchAndMarkets.com is the world’s leading source for international market research reports and market data. We provide you with the latest data on international and regional markets, key industries, the top companies, new products and the latest trends.

Attachment

CONTACT: CONTACT: ResearchAndMarkets.com Laura Wood,Senior Press Manager [email protected] For E.S.T Office Hours Call 1-917-300-0470 For U.S./ CAN Toll Free Call 1-800-526-8630 For GMT Office Hours Call +353-1-416-8900

The global hybrid additive manufacturing market is projected to reach a market size of USD 948.6 million by 2030, with a compound annual growth rate (CAGR) of 22.2% between 2023 and 2030. The adoption of hybrid additive manufacturing in sectors such as aerospace, medical, and automotive is driving this growth. This combination of traditional subtractive manufacturing with additive manufacturing techniques allows for tailored and precise production, with benefits including minimal material wastage, faster production, and cost reduction. The COVID-19 pandemic had a dual impact on the market, causing disruptions in supply chains but also accelerating the adoption of additive manufacturing in the medical field. The titanium segment is expected to experience exceptional growth. The aerospace sector dominates the market, and North America commands the largest share.

Hashtags: #Projected #Million #Valuation

Hgvt.edu.vn trang tổng hợp kiến thức giáo dục, công nghệ, đời sống. Bạn có thể tự đánh giá nội dung và trở thành cộng tác viên của chúng tôi

Hgvt.edu.vn trang tổng hợp kiến thức giáo dục, công nghệ, đời sống. Bạn có thể tự đánh giá nội dung và trở thành cộng tác viên của chúng tôi

Hgvt.edu.vn trang tổng hợp kiến thức giáo dục, công nghệ, đời sống. Bạn có thể tự đánh giá nội dung và trở thành cộng tác viên của chúng tôi

Leave a Reply